Share

Industrial paint room

Endless service innovation, future cooperation enterprising.

Current Product Classification

- Product Description

-

Working principle

◆ When spraying paint:

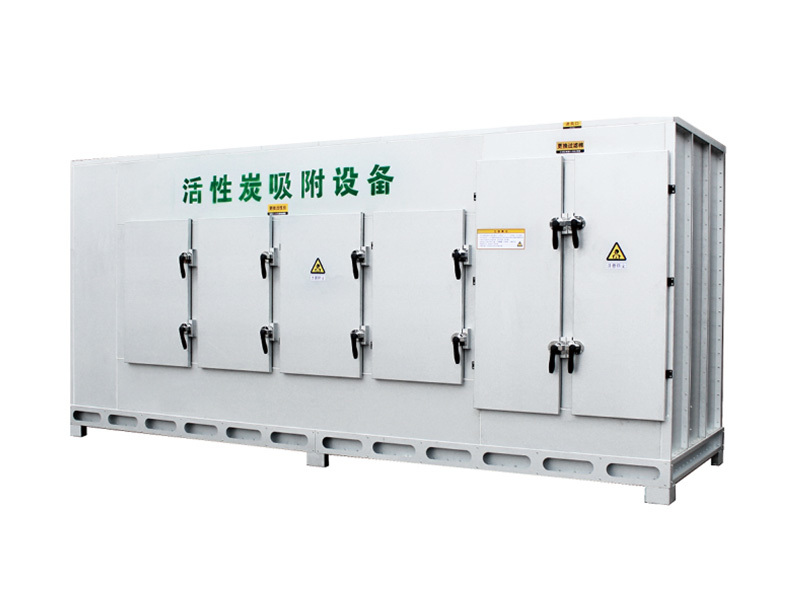

The blower (when the temperature in the spray room needs to be increased in winter, the heater is also turned on at the same time) and the exhaust fan are automatically started in sequence, the fresh air valve automatically opens and the return air valve automatically closes, and the outdoor fresh air enters the blower unit through the primary filter from the fresh air inlet. The fresh air enters the static pressure chamber on the roof after being heated by the heater. The filter top cotton at the bottom of the static pressure chamber balances the air flow and intercepts solid dust. The clean air star laminar flow forms a wind curtain around the workpiece from top to bottom, so that the remaining paint mist of the spray painting does not diffuse to the surroundings. Under the action of continuous airflow, the paint mist descends with the airflow, and after being filtered by the paint mist filter (dry, wet water curtain, water vortex), it enters the activated carbon adsorption box. The organic solvent gas in the paint mist meets the GB16297-1996 atmospheric pollutant emission standard after being adsorbed by activated carbon.

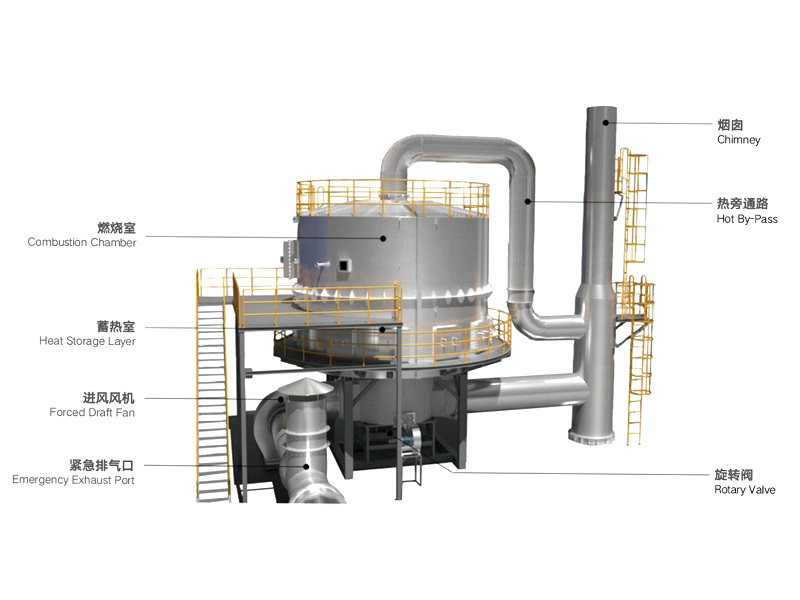

◆ When drying:

Hot air circulation heating is adopted, and the spraying and drying are automatically switched and controlled. The heating energy can be selected as: electricity, natural gas, liquefied gas, diesel, coal.

Consultation

Leave your contact information to get a free product quote.