Share

Activated carbon adsorption equipment

Endless service innovation, future cooperation enterprising.

Current Product Classification

- Product Description

-

Product overview

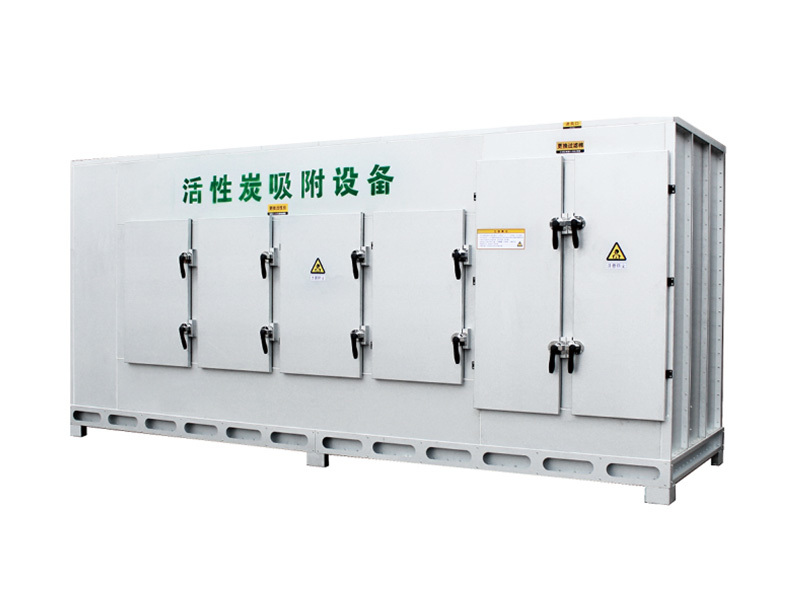

Activated carbon adsorption equipment, also known as activated carbon box, is a high-efficiency, economical and practical purification device newly designed and developed by our company's R&D personnel. It is mainly used for the treatment of VOCS organic waste gas. The VOCS removal rate is as high as more than 80%.

Scope of application

Widely used in traditional processes for treating organic tail gas, such as benzene, alcohol, ketone, ether, alkane, aldehyde, phenol and other waste gases.

Applicable industries: furniture, wood industry, leather making, hardware and building materials, chemical industry, machinery, printing, rubber, electromechanical, automobile, petroleum, etc.

Product advantages

◆ High adsorption efficiency, wide application range, and can treat a variety of mixed organic waste gases.

◆ The equipment has a compact structure, small footprint, full sealing, and can be used indoors and outdoors.

◆ Maintenance and management are simple and convenient, and energy consumption is low.

Product principle

Due to the unbalanced and unsaturated molecular attraction or chemical bond force on the surface of activated carbon, when the surface of activated carbon contacts with gas, it can attract gas molecules, make them concentrate and remain on the surface of activated carbon. This phenomenon is called adsorption. By utilizing the adsorption capacity of activated carbon, the gas contacts with the porous activated carbon with a large surface area, and the pollutants in the exhaust gas are adsorbed on the surface of activated carbon, so that they are separated from the gas mixture, and the purified gas is discharged into the air.

*Honeycomb activated carbon: with its unique honeycomb structure, it has an opening rate of 100%, uniform gas distribution, larger geometric area, and a longer diffusion path. *Primary filter cotton: humidity resistance reaches 100%, and it is washable. It can resist temperatures up to 80℃/176°C: it is non-flammable, has a short automatic extinguishing time, is wear-resistant, and has strong resistance to dust pollution. Compared with other activated carbons of the F1 type, the biggest advantage of the honeycomb is that the pressure loss of the filtering object>5um particles and foreign matter is small.

Consultation

Leave your contact information to get a free product quote.