Share

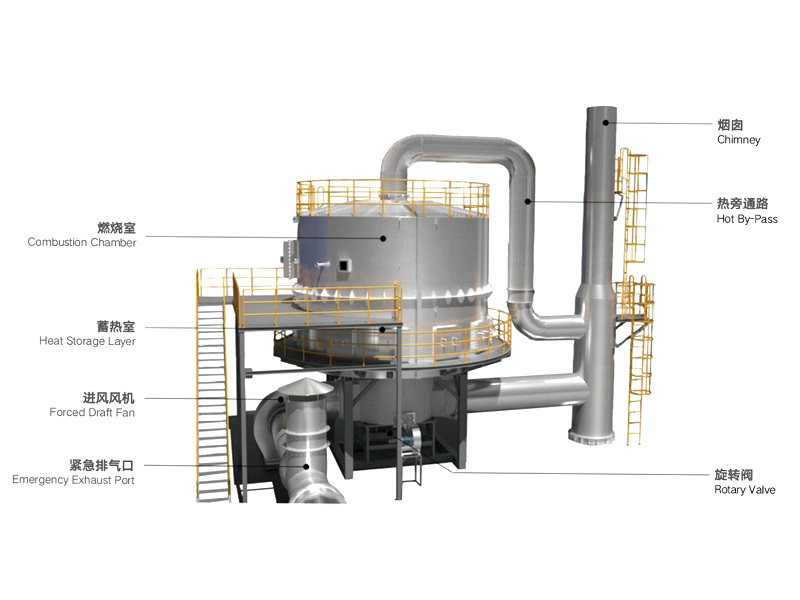

CO waste gas catalytic combustion device

Endless service innovation, future cooperation enterprising.

Current Product Classification

- Product Description

-

Working principle

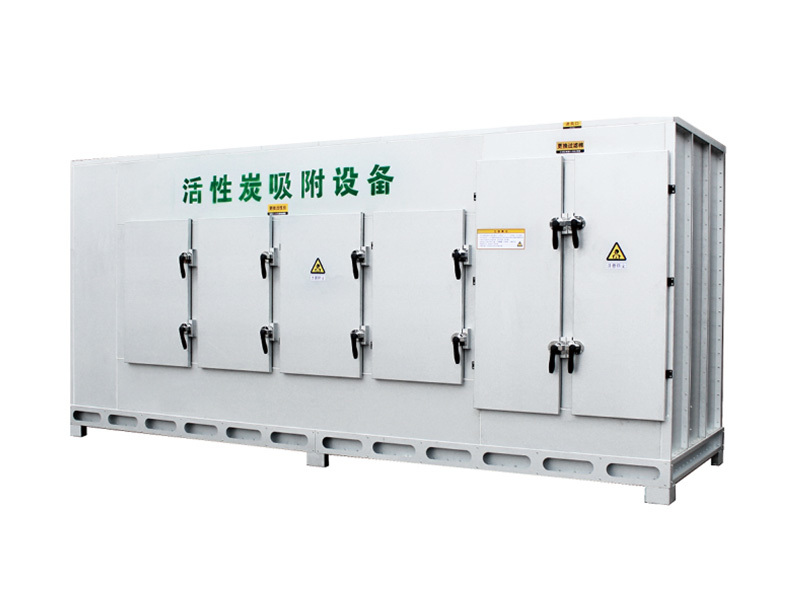

Catalytic combustion adsorption treatment of organic waste gas is to use the characteristics of activated carbon micropores to absorb organic substances, adsorb the organic solvent in the large volume and low concentration organic waste gas into the activated carbon and concentrate it, and the gas after adsorption and purification reaches the standard and is directly discharged. In essence, it is a physical adsorption and concentration process. The organic solvent is not treated. Catalytic combustion desorption is to use the hot air generated after catalytic combustion decomposition of organic waste gas to heat the organic solvent adsorbed in the activated carbon to reach the boiling point of the solvent, so that the organic solvent is desorbed from the activated carbon, and the concentrated high-concentration gas is introduced into the catalytic combustion device. Under the action of the catalyst, the organic substance is oxidized at the catalytic ignition temperature of 200-600℃ and converted into harmless water and carbon dioxide and discharged into the atmosphere.

Since this reaction is a chemical reaction process, not an open flame combustion, it is safe and reliable, and can completely solve the secondary pollution during desorption.

System composition

The system is mainly composed of air pre-treatment filter, switching air valve, combustion furnace, combustion system, combustion-supporting system, compressed air system, exhaust system, etc.

Product advantages

◆ Easy to operate: Automatic control is achieved when the equipment is working.

◆ Low energy consumption: After the equipment is started, it only takes 15-30 minutes to heat up to the ignition temperature, and the energy consumption is only the machine power. It is automatically compensated when the concentration is low.

◆ Safe and reliable: The equipment is equipped with a fire-retardant dust removal system, an explosion-proof pressure relief system, an over-temperature alarm system and an advanced automatic control system. Low resistance.

◆ High purification rate: It uses today's advanced precious metal palladium and platinum impregnated honeycomb ceramic carrier catalyst with a large specific surface area.

◆ Residual heat can be reused: Residual heat can be returned to the drying channel to reduce the power consumption in the original drying channel; it can also be used as a heat source for other aspects.

Consultation

Leave your contact information to get a free product quote.