Share

RTO waste gas treatment

Endless service innovation, future cooperation enterprising.

Current Product Classification

- Product Description

-

RTO principle

RTO (Regenerative Theral Oxddizer, referred to as RTO), its basic principle is to oxidize organic gas to generate CO2 and H20 at high temperature (>760℃), thereby purifying waste gas, and recovering the heat released during decomposition, so as to achieve the dual purpose of environmental protection and energy saving. It is an energy-saving and environmental protection device used to treat medium and high concentration volatile organic waste gas.

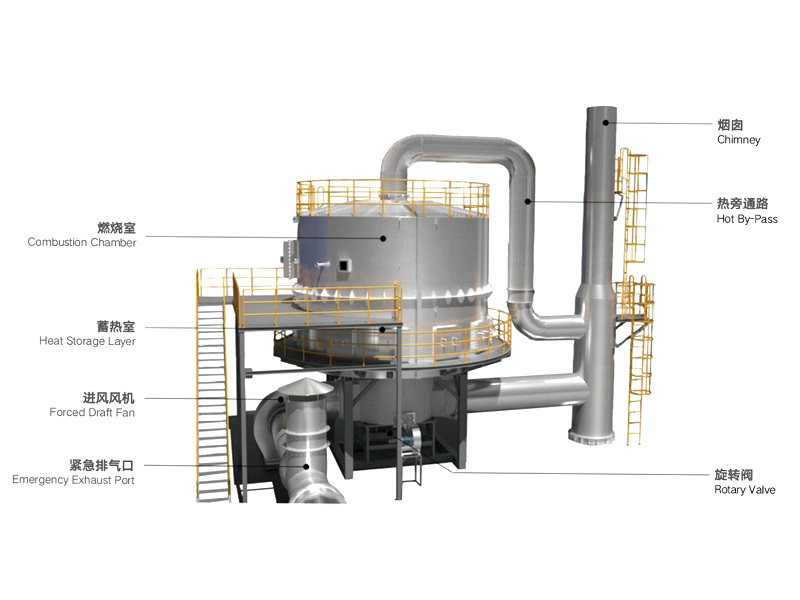

RTO structure

12-chamber structure

The rotary thermal incineration equipment produced by our company adopts a 12-chamber structure, which divides the heat storage chamber into twelve equal parts, five of which are air intake areas, five are exhaust areas, one is a purge area, and one is a blind area.

◆ Air intake

The gas to be treated enters from the air intake area, passes through the heat storage ceramic layer, the gas is heated by the ceramic, the gas temperature increases, the heat storage ceramic is cooled, and then passes through the oxidation chamber, the gas is purified.

◆ Exhaust

The purified gas passes through the exhaust area, the heat in the gas is absorbed by the heat storage ceramic, the ceramic heats up, the gas is cooled, and the cooled gas is discharged into the chimney.

◆ Purge

The purge fan purges the purge area to prevent the unpurified gas from being discharged when the air intake area is transferred to the exhaust area. The blind area is not ventilated to prevent gas mixing. Through the rotation of the rotary valve, the ceramic packed beds in each area are heated, cooled, and purged in a cycle to complete the gas purification function and recycle heat.

Consultation

Leave your contact information to get a free product quote.